Telescopic Hydraulic Cylinders

Application Specific Telescopic Cylinder SolutionsTelescopic hydraulic cylinders, with their multi-stage nested design, provide an extended working stroke while maintaining a compact retracted form. At Goa Hydraulics, we engineer telescopic cylinders customized to meet the specific demands of your applications and environments. Our expert engineering team collaborates with you to address key design considerations, ensuring the cylinder aligns with your unique requirements. We offer a variety of telescopic cylinder configurations, including:

Designed for Your Equipment and ApplicationOur tailored designs deliver optimal performance for your custom telescopic cylinder, addressing your equipment’s specific needs. With extensive experience across diverse markets and hydraulic applications, we create solutions that handle your toughest challenges. Common applications for our telescopic cylinders include:

|

|

Features and Specifications of Custom Telescopic Hydraulic Cylinders |

|

|

|

|

|

|

|

|

Single-Acting Telescopic CylindersSingle-acting telescopic hydraulic cylinders rely on hydraulic pressure to extend and use gravity or external mechanical force to retract to their original position. These cylinders are low-maintenance and suitable for a wide range of machinery.

|

Double-Acting Telescopic CylindersDouble-acting telescopic hydraulic cylinders use hydraulic power for both extension and retraction, making them ideal for heavy-duty applications. Unlike single-acting cylinders, they do not rely on gravity or external forces for retraction.

|

|

|

Partially Double-Acting Telescopic CylindersPartially double-acting telescopic cylinders are commonly used in over-center applications. These cylinders generate retract force for part of the stroke, with gravity completing the retraction cycle.

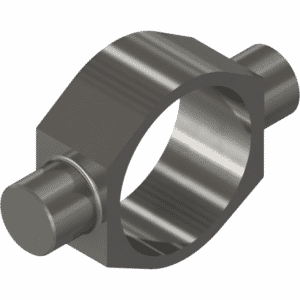

Enhance Your Cylinder with Special Features

|

|